1

Q: What is the available thickness range, and how precise can the customization be?

A: As the direct manufacturer, we can produce neoprene rubber sheets in a wide range of thicknesses, typically from 1mm up to 50mm or more, based on your project needs. Our production process allows for precise calibration, ensuring the thickness of your order is consistent and meets your exact specifications, whether for precise gaskets or thick padding.

2

Q: Can we customize other properties besides thickness, such as density, color, or surface finish?

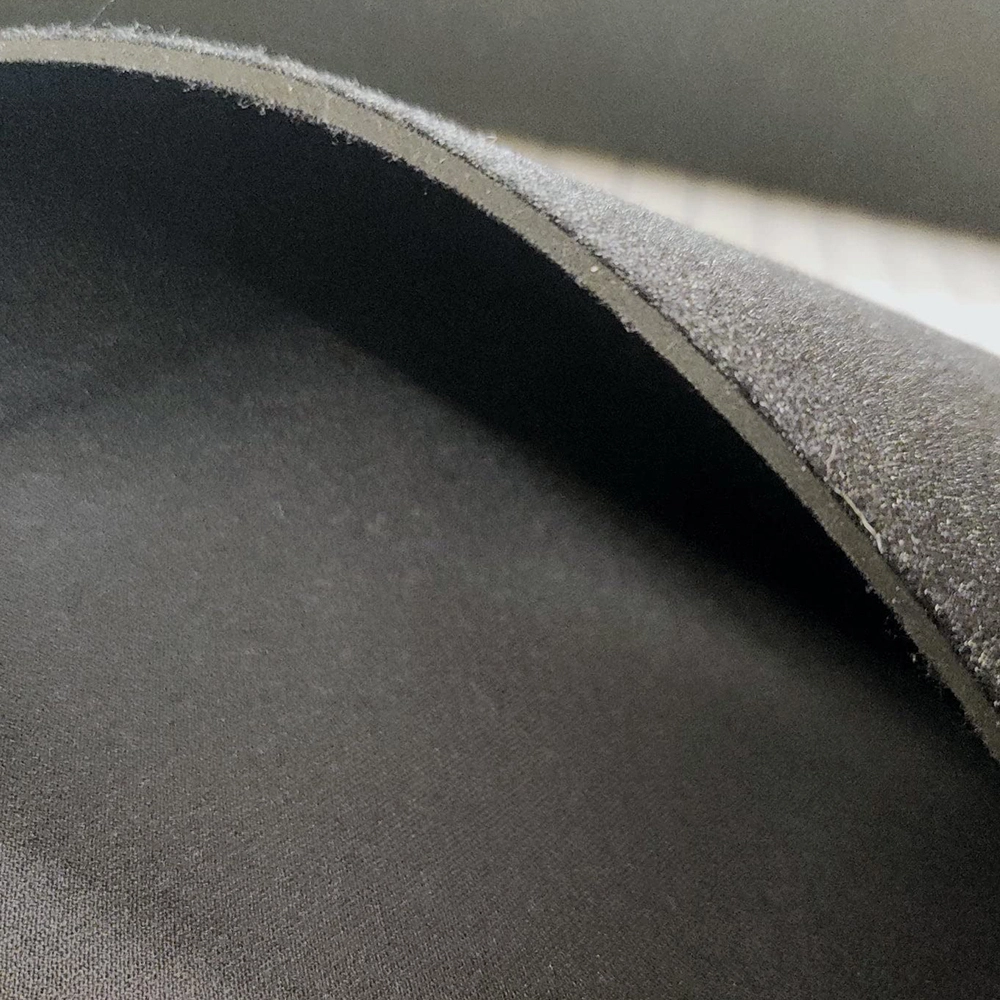

A: Yes, full customization is our core strength. In addition to thickness, we can adjust the rubber compound to achieve specific densities (soft, medium, firm), produce sheets in standard or custom colors, and offer different surface finishes (smooth, textured, fabric-backed). As your factory partner, we work with you to develop the exact material profile required.

3

Q: What are the key advantages of sourcing wholesale sheets directly from your factory?

A: Sourcing directly from us provides multiple benefits: Significant Cost Savings (factory-direct pricing with no distributor markup), Guaranteed Consistency (our vertical integration ensures every batch meets the same high standard), Total Customization Flexibility, and Direct Technical Support. You get a tailored material solution with optimal value for bulk purchases.

4

Q: What are the primary applications for this type of neoprene sheet?

This versatile material is widely used as a base material for DIY crafts and prototypes, including shock absorption and cushioning pads, luggage, sports and fitness equipment protective covers and liners, as well as various clothing accessories (such as

life jackets, diving suits, diving hat accessories, toys, etc.) and merchandise gifts (such as Koozes, bottle sleeves, laptop bags, neoprene bags, etc.). Our team can provide the best specification recommendations for your application.

5

Q: Do you provide samples, and what is your typical lead time for bulk production orders?

A: Yes, we encourage sampling. We can quickly provide small swatches or sample sheets of your specified thickness and formulation for testing and approval. For bulk production, lead times are competitive and depend on order size and specifications. Our integrated manufacturing allows for efficient scheduling, ensuring reliable and timely delivery for your wholesale supply needs.

6

Q: Why is purchasing directly from your factory more advantageous for OEM clients?

A: Sourcing directly from libra neoprene, the manufacturer, provides significant cost savings by removing distributor markups. It also offers complete transparency and control: you communicate your specifications directly to our production team, ensuring the final product matches your exact requirements for quality, dimensions, and finish. This direct relationship translates to better pricing, clearer communication, and more reliable supply for your projects.

7

Q: What specific aspects of the 3mm sheet can be customized for our OEM project?

A: We offer comprehensive OEM customization. Beyond the standard 3mm thickness, you can specify: sheet dimensions and roll lengths, surface finish (e.g., smooth, textured, nylon/lycra-backed), rubber compound density and firmness, color (standard or Pantone-matched), and even custom packaging for branding or logistics. We act as your material development partner.

8

Q: How does your factory ensure consistent quality and thickness across bulk orders?

A: Our vertical integration is key. We control the entire process—from mixing the raw chloroprene compound to calendering (precision rolling) and vulcanization. This allows for strict in-process quality checks at every stage. We use calibrated equipment to ensure every sheet meets the specified 3mm thickness tolerance and maintains uniform density, which is critical for your manufacturing consistency.